You can use glue instead of solder when joining two pieces of metal together, but it will not be as strong of a connection.

Yes, you can desolder with a soldering iron. You will need to use a soldering iron with a pointed tip and apply heat to the solder joint. Once the solder melts, you can remove the component from the board.

Yes, you can solder wick with copper wire. This is because copper has a relatively high melting point and is a good conductor of heat. This means that it can be used to create a strong bond between the wick and the wire.

If you need a quick solder job and don't have any soldering supplies on hand, you can try using staples. Just be warned that this is not a permanent fix and the connection may not be as strong as if you had used traditional soldering methods.

4.9/5

$234

I'm in love with a new tool, which doesn't happen frequently. This is, without a doubt, the greatest method for removing lead-free solder from PCBs. A single pull of the trigger is all it takes to remove the solder. No torn traces. Remaining clean PCB Cleanup takes no more than five minutes. includes a casing and a 1.0MM tip. Although expensive, the tips are worthwhile.Therefore, purchase this if you're sick of damaging traces, scorching PCBs, or pumping the manual suction tool 20 or 30 times only to miss half the solder. Don't waste any more time. You won't be sorry! I'll let the photographs, which were taken only with this tool, speak for themselves.Keep in mind that some leads from the PCB you are removing the solder from will still be wedged inside the vias. The component can be removed by giving it a brief tap with another instrument (not the tip, unless you intend to replace them frequently).My only issue is with the 90-day warranty! Truly, Hakko? One point deducted for the avaricious bean counters at Hakko USA who decided to limit the product's warranty to a 90-day period for US customers. Despite being manufactured in Japan, Hakko only offers a 90-day warranty on its goods.If I publish the warranty link, the Amazon bots will penalize me; instead, search for "Hakko Warranty" to find out more information. Here is a brief explanation of what is covered for the first 90 days and during the entire first year of the warranty, which is solely the heating element. 1 year warranty on the heating element (with a ton of restrictions; use Google to find the conditions of the guarantee on the Hakko website) Sensors: 1 year and up Buttons, switches, and other items of contact - 90 days plus 90 days plus for the suction motor Attachment - 90 days The remainder - 90 days

4.8/5

Designed to leave a residue that is environmentally safe

Static free bobbins

NSF - Nonfood Compounds Program Listed P1, NSF Registration #144208

Oxide-free clean copper

Manufactured under SPC guidelines

Only pure type 'RMA' rosin is used meeting the requirements of MIL-F-14256F (ANSI/J-STD-0004)

ESD Safe Spools - Yes

$234

There aren't many words I need to say here. Fantastic product! work perfectly for me. But if you're interested, simply look at the picture. manufactured in Japan. Of course, everyone is aware of what Japan quality means in the field of electronics. I was genuinely astonished. For a price in that area, I was anticipating some cheap Chinese crap.

4.7/5

100% copper wick has fine braid design to promote strong capillary action to pull in excess solder

Removes up to four times more solder than conventional wick, and extracts solder much faster than wicks based on Type-R fluxes

Residue left behind is halide free and non-conductive, so it does not have to be cleaned off the board

Available with standard or anti-static bobbins

$234

This works far better than the inexpensive stuff you can find from time to time, I assume because of the tighter weave and perhaps some treatment inside. Although it cost extra, it is effective. I was removing headers with through holes. Previously, I crushed the header, pulled the pins out one at a time, and used inexpensive wick to remove the majority of the solder. AFTER that, sucking out the last of the solder from the through holes. They had to be completely clean for me to add new headers. On the first stage, this NTE stuff pulled all the solder out. I simply pressed it against the pin and inserted a large chisel tip, and it sucked up so much solder that the pin came out by itself. I didn't have to spend the time crushing the header for successive boards. I just removed all of the solder from each pin before removing the header. Since it came out so nicely, I'm very sure I could have utilized the header again. helped me avoid a lot of time and hassle. If you don't already have this wick and find de-soldering frustrating, purchase it now.

4.6/5

NSF - Nonfood Compounds Program Listed P1, NSF Registration #154374

Static free bobbins

Flux residue is non-conductive and non-corrosive

High SIR-meets the requirements of both the bellcore specification TR-TSY-000078 and IPC test method III

No clean super wick

Flux residue remaining on board does not have to be cleaned

$234

I went hunting for some nice wick to utilize because I was having trouble using some Radio Shack brand wick I had lying around from earlier in my life.All I can say is that this specific wick could only be improved by heating up on its own! The braid was too loose and the Radio Shack material's strands were too large. Of course, additional flux is required to utilize this or any wick. I purchased more at the same time as this because I was aware of it before entering (also by MG Chemicals).I appreciate MG Chemicals providing such a great wick. When I run out, I'll place another order.Anyone having trouble utilizing this is advised to read this. It is incredibly challenging to get ANY wick to wick with lead-free solder or oxidized solder joints. Applying flux (highly activated flux works best on oxidized joints) and a small amount of leaded solder is the trick. If so, this wick will quickly clean it up!

4.6/5

Price For: Each Braid Material: Copper Width: 2.5mm Length: 50ft Braid Color: Blue Leaded Process Compatible: Yes Roll Length: 50ft RoHS Compliant: Yes

$234

The pricing per foot was what convinced me to buy the entire 50-foot roll of the Chemtronics desoldering braid. I've been soldering for more than 30 years, and this desoldering tool is the best I've ever used. The copper braid is of the highest grade and is FINELY braided so that it sucks up the solder very quickly. Although it almost seems too gorgeous to use, you definitely will! When using lead-free solder or old, oxidized solder joints, I make sure to use flux and I'll place a fresh drop of clean solder on the joint I'm desoldering so that the whole thing melts quickly. I typically cut a piece from the reel and hold it with pliers to avoid heating up my fingers. I dip the wik in flux before using it when I use flux to ensure that everything flows smoothly. You won't be sorry you bought this. The money was well spent.

4.4/5

Price For: Each Braid Material: Copper Width: 2mm Length: 5ft Braid Color: Green Braid Size: #3 Features: Packaged in ESD-Safe Static-Dissipative Bobbin Flux Type: Rosin Activated RA Leaded Process Compatible: Yes RoHS Compliant: Yes

$234

This stuff functions fairly well. With some needle-nose pliers, I prefer to hold a 1" piece in the middle while cutting it, then I use each end once. I've discovered that pressing down with your soldering iron while laying it over the solder you wish to remove works best.It won't, however, suction solder from holes. You can clean up almost anything if you use a good solder sucker together with a resistor lead to remove solder from holes when the solder sucker isn't working.

4.4/5

$234

I really enjoyed using this wick. In comparison to the $7 or $8 braids, the braid is a little looser. However, I discovered that technique was very useful for removing solder from confined spaces. The strands would begin to open up a little, and the braid would swiftly assume the shape of a corner, possibly. I could see the rosin begin to smoke when the iron's conductivity was good, and the solder would then just "wick" up. In the past, when desoldering, I've burned out a number of pads or lifted a lot of them. I used this wick and didn't lose a single pad. I simply find it too challenging to operate with the tighter wicks, which causes me to overheat and ruin the joint (jumper wire time). Not when it comes to this. In any case, for me. :-)

4.3/5

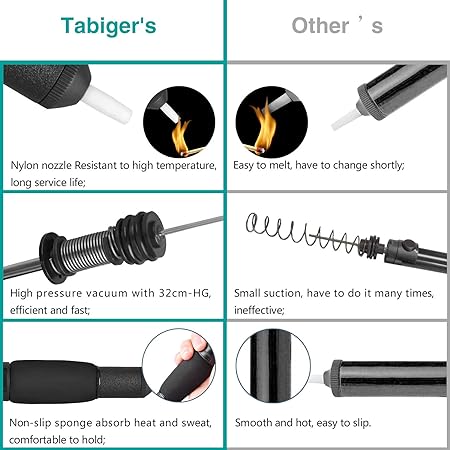

Top-notch Quality. The solder sucker has an aluminum bronze frame and a high pressure vacuum which can remove solder from a printed circuit board effectively.

Compact and Lightweight. Measuring 7.48''X0.79'', the desoldering pump can be used with only one hand, either your right or left hand.

Solid Construction. The solder sucker has plastic backing to ensure stability.

Pure oxygen free copper wire, no clean flux for easy to use. The solder wick can help clean some residue flux and BGA thermal bonding pad too.

Solder Wick Braid. The desoldering wick is 2.5mm wide and 1.5m in length. Weight: 0.4oz. With low residue design, this solder braid will help clean spare solder on the pin away to avoid short circuit, especially in small, hard to reach areas.

$234

Although it's not very well crafted, it works. When pressing the plunger, the main body's loose plastic threads can occasionally cause it to detach. A little pipe clamp placed on it will aid in keeping it in place. Also not smooth, the plunger doesn't always latch on the first try. However, once it does latch, it does work to pull firmly on the solder.UPDATE: OMorc complied with their guarantee and replaced my unit with a new model that addresses all of the aforementioned problems. The new model is a single barrel construction and lacks threads, the replaceable tips use a quarter twist lock, and the plunger action is incredibly smooth and latches every time. They deserve five stars since they truly stand by their goods.

4.3/5

ã€Desoldering Wick with copper braid】 2pcs solder braid with the size 2.5mm Width, 1.5m Length, this desoldering wick has geometrically-precise weave with copper and rosin, work from the tip of the desoldering wick, once the desoldering wick and the solder has been heated, the solder braid can quickly absorbed molten solder and left a clean working area.

ã€3-in-1 Solder Removal Tool】 1pcs desoldering vacuum pumps and 2pcs solder wicks, a must-have tool for electronics kit, the desoldering wick absorbs solder, the desoldering pump pulls it away quick, while the solder wick is better for small amounts of solder, the solder sucker takes up large amounts.

ã€ABS body with non-slip sponge and Nylon nozzle desoldering pump】 The body of the desoldering vacuum pump is made of high quality ABS, which make the solder sucker delicate and durable, also the covered sponge can absorb sweat and heat, make it comfortable to hold, the nylon nozzle of the solder suck can endure high temperature, thus it can be used for a long time.

ã€Widely used Solder Remover】 The Desoldering Wick & Desoldering Pump can be used to correct mistakes with small boards on PCBs, remove relays and other components from printed circuit boards, re-solder mechanical keyboard switches, unsoldering old wire from devices, desoldering computer parts such as a motherboard,clean alloy on smd components and more.

ã€One-handed solder sucker with powerful suction 】 Whether you are right or left-handed, you can using the desoldering pump by just cocking it and pressing the trigger button with one hand when you are ready, the desoldering pump designed with double ring double open and "vacuum" button, which make the sucking power awesome.

$234

This desoldering pump is simple to use and works surprisingly effectively. This one seems to be well manufactured in comparison to cheaper ones that only last for one or two uses before breaking or dying. Solid plastic with a teflon tip and metal rod make up the construction; it is one piece and cannot be opened for cleaning, however the solder tends to slip out immediately after usage. Easily held and suckers up a good blob of solder at a time. The foam ring is appropriately padded. The wick seems a little cheap, and I don't think there's any flux in it; I had to add flux before it would wick any solder. Purchase this for the pump. I was expecting this would be the same type of spool of wick that I had from Radio Shack in the past, but it doesn't perform as well. If I mix some flux with the solder I'm attempting to remove, it will still work. Though obviously no match for a decent Hakko desoldering gun, the pump is a reasonable bargain overall and superior than the extremely cheap ones.

4.2/5

High quality material - the desoldering pump body made of premium quality ABS material, with non-slip sponge and nylon nozzle, anti-static, heat resistant and durable

Wide application - correcting mistakes on small PCB boards, removing relays and other components from printed circuit boards, cleaning small components, re-soldering and desoldering

7-in-1 solder removal tool - 1pcs solder sucker and 6pcs solder wicks in 3 size

High efficiency solder sucker - the desoldering pump designed with double ring and "vacuum" open button, you can remove solder from circuit board effectively by cocking it and pressing the trigger button with one hand

Desoldering braid wick with rosin - 6 pieces copper solder braid in 3 size, width 2.0mm/2.5mm/3.0mm, length 1.5m, 2 pieces for each size; geometrically-precise weave, can be used to clean the spare solder on the pin away to avoid short circuit, to meet your various of soldering needs

$234

You are aware of how difficult it is to locate soddering wick. OMG, no one in my town has even heard of it. Lows, Home Depot, Walmart, craft stores, you name it, none of them. And you get a lot for a great price. The sodder sucker is an added plus.

A desoldering wick is a long, thin strip of copper that is used to remove solder from electronic components. It is placed over the solder joint and heated with a soldering iron, which melts the solder and wicks it away from the joint. Desoldering wicks are an essential tool for anyone who works with electronics, and are especially useful for repairing circuit boards. They can be used to remove excess solder, to repair damaged solder joints, and to clean up solder messes. Desoldering wicks are relatively inexpensive and can be found at most

Flux is not strictly necessary for soldering, but it can make the process easier and produce a better result. Flux helps to remove oxides from the surfaces to be soldered, preventing them from re-forming and making it easier for the solder to flow and adhere. It also helps to prevent oxidation of the solder itself.

If you don't have a desoldering iron, you can still desolder components from a circuit board. You will need a soldering iron, some solder wick, and some flux paste. First, heat up the soldering iron and apply some flux paste to the area where you want to desolder the component. Then, place the solder wick over the component lead and heat it up with the soldering iron. The solder should wick up into the solder wick. Repeat this process until the component is free from the circuit board.

If you need to desolder something without using a soldering iron, there are a few methods you can try. One is to use a desoldering braid, which is a type of copper wire that absorbs solder. Another is to use a desoldering pump, which is a tool that sucks up solder. You can also try using a heat gun to melt the solder, but be careful not to damage the component you're trying to desolder.

If you need to remove old solder from a circuit board or other electronic device, you can do so with a soldering iron and a desoldering pump. First, heat the solder with the soldering iron until it is melted. Then, use the desoldering pump to suction the molten solder from the device.

COPYRIGHT © 2019